A New Way to Make Shoes

Prior to founding FUSE, Tory worked as an industrial designer within Nike’s Advanced Product Engineering Group or APE. On of the projects was to hunt for new opportunities within the Basketball category. Tory was in a small team that included former Ford Engineer, John Tawney. Tory and John had a dual agenda: Of couse we wanted to uncover a great opportunity for Nike Basketball, but they also wanted to reduce the labor it takes to build a pair of basketball shoes. The team presented a handfull of good ideas including this one that was titled as “Game Day”. The idea was to make a super lightweight shoe that would allow players to practice all week in their heavier training shoes and then jump higher and run faster on Game Day with these lighter kicks. We built the first prototype shoes out of molded EVA only. No heavy outsole, so the shoes were feather light.

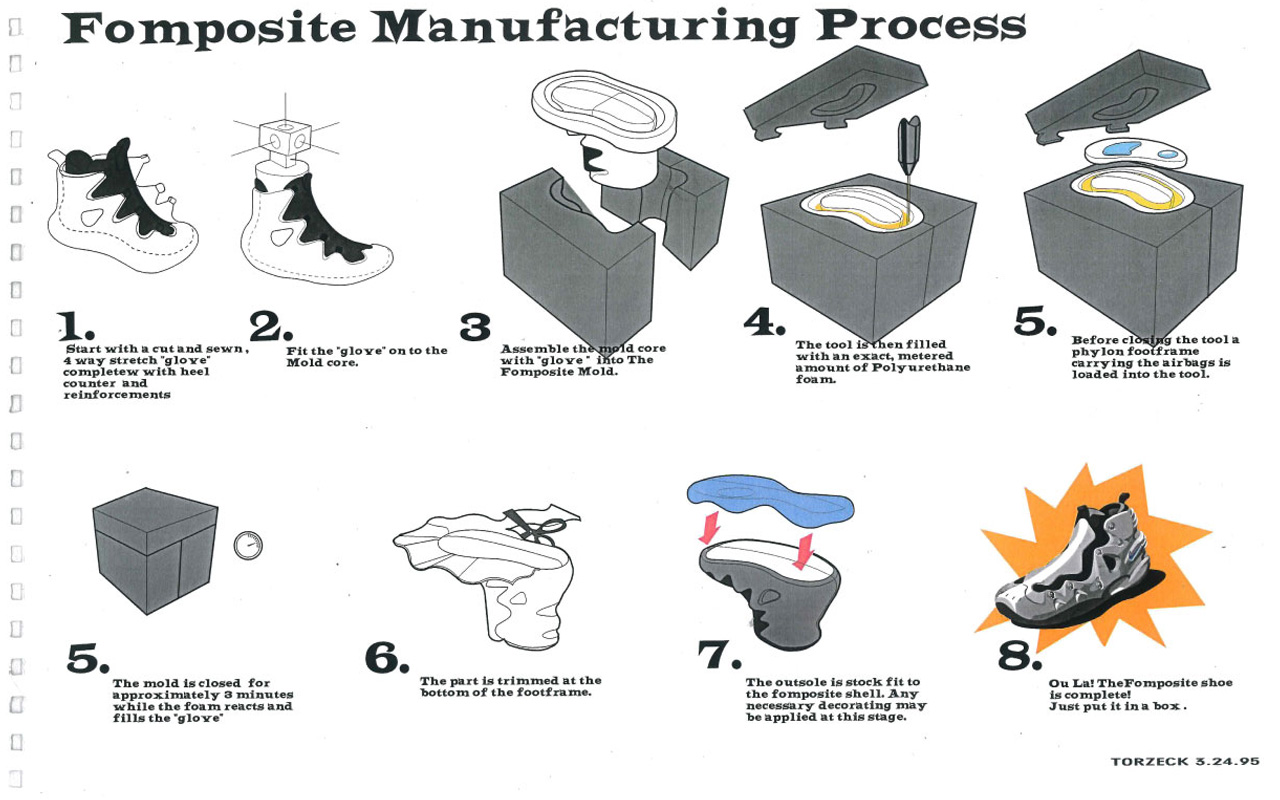

The shoes were great but had a too short life span so John put a 4 way stretch fabric skin around the pre-molded form and compressed it. It was amazing. Super light and super strong. A true composite. At a review their boss asked Tory what the technology was called and Tory spouted “FOAMPOSITE”. The name stuck.

Beyond the advantages for better fit, visually Foamposite afforded designers the ability to play with form and really sculpt their products.

Soon after, the project headed to Nike’s Taiwan R and D facility for commercialization. The team there traded compression molding for pour-in- place molding using liquid polyurethane. John and Tory are both on the patent.